-

Rubber Process Machine

-

Rubber Mixing Mill Machine

-

Rubber Powder Production Line

-

Rubber Kneader Machine

-

Rubber Banbury Mixer

-

Rubber Vulcanizing Press

-

Reclaimed Rubber Sheet Line

-

Plastic Recycling Line

-

Tennis Ball Making Machine

-

Rubber Grinder Machine

-

Batch Off Rubber Cooling Machine

-

Rubber Conveyor Belt Production Line

-

Rubber Calender Machine

-

double scerw extruder

-

Circular Automatic Small material Weighing System

-

Automatic Small Material Weighing System

Excellent Quality Rubber Lines Metering Systems Small Materials Automatic Metering Equipment

| Type | Chemical Batching Machine | Video Outgoing-inspection | Provided |

|---|---|---|---|

| Machinery Test Report | Provided | Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump |

| Tire Machine Type | Tire Forming Vulcanizer | Voltage | 380 V |

| Dimension(l*w*h) | 5m*5m*2m | Warranty | 1 Year |

| Key Selling Points | Automatic, Multifunctional, Competitive Price, High-Accuracy, High Safety Level, Energy Saving, Eco-Friendly, Long Service Life, High Productivity, Easy To Operate, Flexible Manufacturing, IOT, Remote Monitoring, Digital | Power (kw) | 30 |

| Weight (kg) | 1000 | End Product | Rubber Products |

| Raw Material | SS304 | Function | Automatic Weighing |

| Keyword | Automatic Weighing, Chemical Batching, Small Material Weighing System | Final Product | Motorbicycle Tyre,tyre, Rubber O-ring, Tube, Rubber Products |

| Advantage | High Producing Efficiency | Capacity | 15 Tons |

| Machine Structure | Modern Frame Structures | Feature | Efficient And Eco-friendly |

| Control System | PLC+touch Screen | MOQ | 1 Set |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Hydeco always adheres to the customer-centricity, followed the business philosophy of "integrity, win-win and innovation", with the goal of "creating high-quality products" and the purpose of "customer satisfaction" to provide each customer with a cost-effective technical solution.The series of products have achieved mutual combination of standard and non-standard design.Through the perfect technical management system, quality assurance and customer service system, the comprehensive quality and service of products have reached the international level.

![]()

![]()

![]()

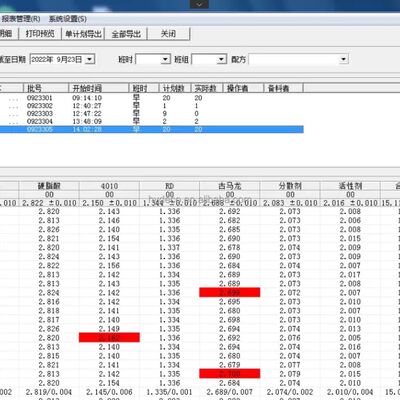

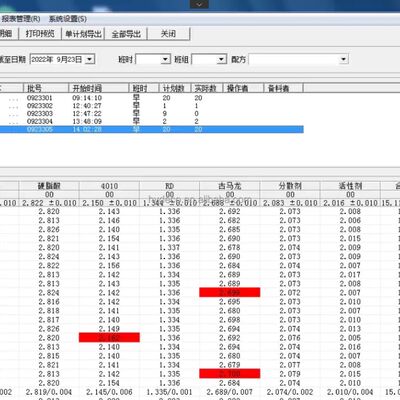

Is the automatic small material weighing system suitable for the rubber industry?

Yes, it is tailored for the rubber industry, focusing on small material weighing and batching needs in rubber production.

What are the core features of this weighing system?

It supports single-scale or multi-scale simultaneous weighing, high-precision batching, automatic workstation selection, and centralized dust treatment. It also has small footprint and low maintenance requirements.

How does the system ensure high weighing accuracy?

Its weighing unit adopts independent design-platform scale and conveyor line are completely sepa-rated. This not only guarantees accuracy but also shortens weighing self-stabilization time and extends platform scale service life.

What types of feeders does the system use, and how to adjust feeding?

It is equipped with two feeder types: electromagnetic vibration feeders and spiral feeders. You can adjust amplitude and frequency to switch between high, medium, and low feeding speeds, balancing shortest batching cycle and highest accuracy.

Can the system be installed in common workshops?

Yes, it can be arranged in one-story factory buildings. lt uses a steel structure platform with built-in unpacking and feeding dust removal devices to handle dust from weighing and unpacking.

What control functions does the system have?

It adopts computer network control, supporting on-site and remote formula management, data

reporting, plan management, material statistics, and alarm interlocking.

Is the system easy to expand for future needs?

Yes, its weighing and conveying devices are in linear layout, and weighing units can be assembled

flexibly, making expansion easy.